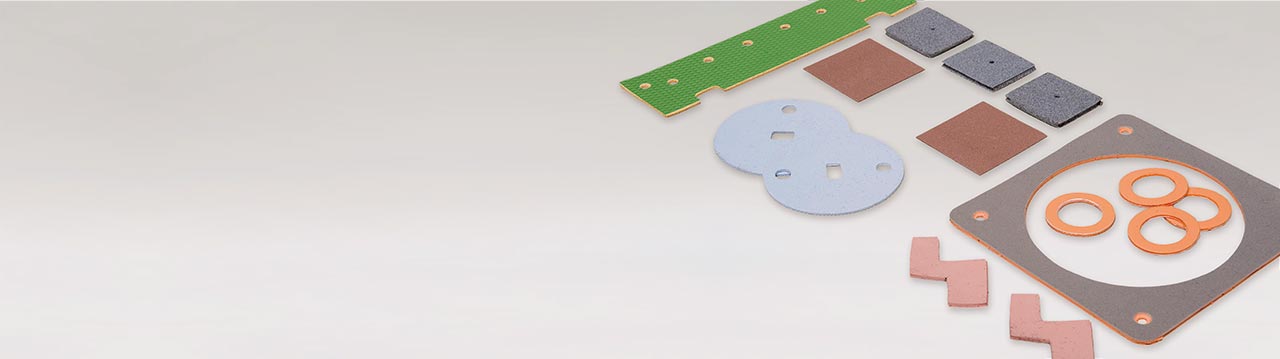

Thermally conductive foils are effective, versatile and indispensable for dissipating heat from electronic circuits.

Electronic components generate heat loss. In order to avoid component overheating and thus damage caused by heat jams and to dissipate the heat in a controlled manner, thermal conductive films are indispensable.

Thermally conductive foils are designed for use where solid thermal and electrical properties are required at a low cost.

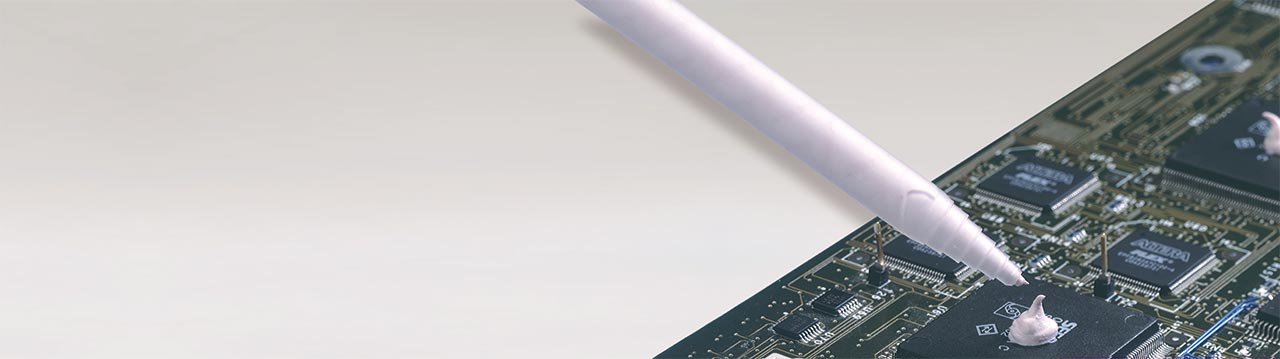

Other products

- Phase change material (low therm. impedance/compensation of the smallest surface unevenness)

- T-Wings (surface-enlarging laminate/electrical insulating)