Customer specific consignments

Configurations as requested

Immediate model proofing makes your decision easier. Bog-standard does not apply here. Direct access to the production lines enables us to implement all of your customised, specific requirements to manufacture precise cuttings, punched or moulded products using the most up-to-date technology and top quality materials.

Our extensive product and service competence makes us the ideal contact partner for all of your questions and requests.

Configuration as requested – Part production using water-jets

Those who need absolute high precision decide to cut their goods using high-pressure water jet process – a trend technology. Machining length accuracy of up to 0.005 mm/m can be realised using this process. Virtually all materials can be processed.

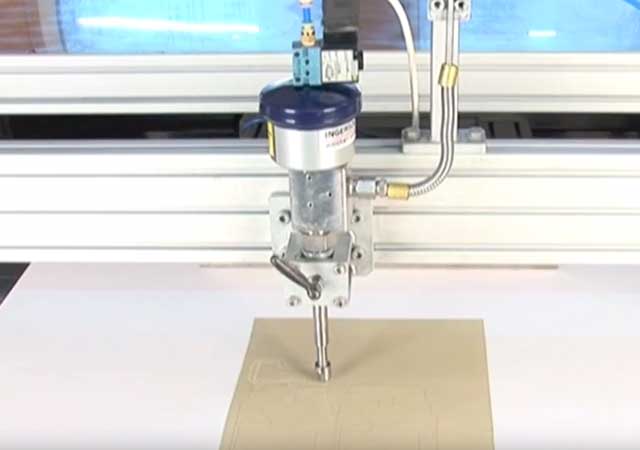

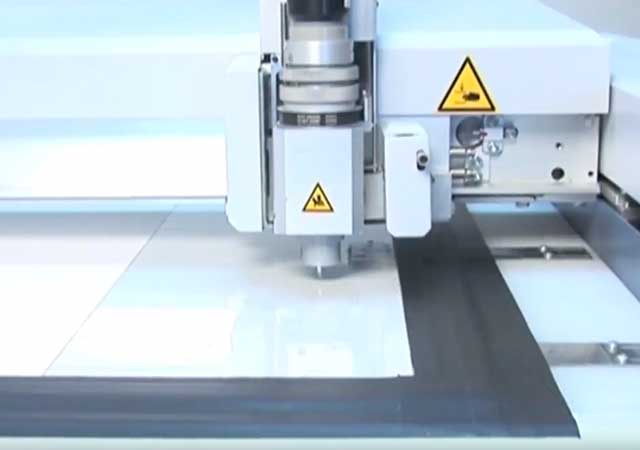

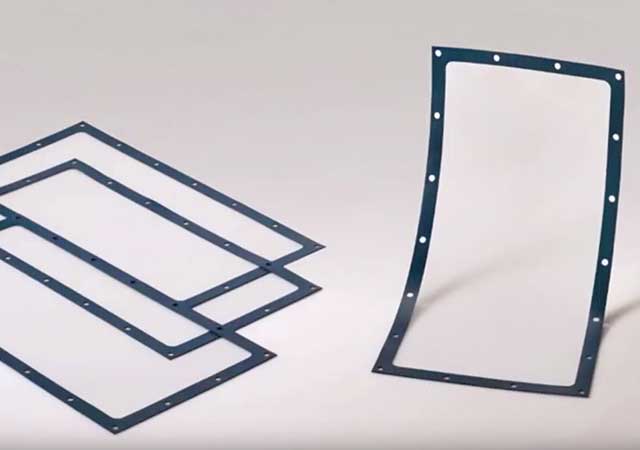

Shaped parts produced by a cutting plotter

Our modern cutting plotters use CAD data / DXF drawings to procedure the patterns. Our precision plotters meet all of your needs – and they are customised to your specifications.

Punches

All-metal toolpieces mounted on heavy-duty punches (high-speed Baier press). Kiss-cut parts are used for your applications in our heavy-duty punches in order to make them both flexible and fast for producing small to huge batches of items.

“Cut-to-length” sections (raw material sections cut to the specified length)

The raw materials are automatically trimmed and cut to the finished shape. The cuts are made without any problems arising from using different materials. The processing speed and the precision guarantee optimum results.

Production of dispenser gaskets and O-rings

The production of dispenser gaskets and O-rings involves manual work. An instinctive touch is needed to produce the final assembled result using a so-called compound after the extruded EMI elastomer has been trimmed. The material is pressed at a pressure of 1t and a temperature of 200°C and a special tool has to be used to vulcanise the bonded areas. The final process is the deburring of the O-rings.

Kiss-cut rolled goods

Perfect cuts, precision and non-wearing processing thanks to kiss-cut punching (it is only the backing material that is punched out).

Die-cut toolpieces mounted on swing-beam punches – Swing-beam press

Customised solution competence. Using of our heavy duty punching presses will bring maximum flexibility and versatility as well as a wide range of application options to your punching and stamping processes.

The die-cut toolpieces are produced in different shapes and sizes – all of them customised to meet your specifications and requirements. We will be delighted to supply your toolpieces.

Kontakt

E. S. Electronic Service GmbH

Hohe Straße 3

61231 Bad Nauheim

Telefon: +49 (0) 6032 9636-0

Telefax: +49 (0) 6032 9636-49

E-Mail: info@electronic-service.de

CONTACT

E. S. Electronic Service GmbH

Hohe Straße 3

61231 Bad Nauheim

Phone: +49 (0) 6032 9636-0

Fax: +49 (0) 6032 9636-49

Email: info@electronic-service.de

ABOUT US

The E.S. Electronic Service GmbH produces and markets customer-oriented solutions worldwide. In doing so, we concentrate our resources on electronic components, materials with a focus on EMI shielding, heat conduction, as well as noise filters and absorbers.