Thermal Conductivity Measurement FAQs

Parker Chomerics is one of the world’s leading manufacturers of thermal interface materials and we are the only Parker Chomerics dealer in Germany to reliably supply the Central European region. Over the years we have received many questions from customers about the measurement and testing of Parker Chomerics thermal interface materials.

We have therefore put together a few questions and answers for you.

What test method does Parker Chomerics use to characterize thermal interface material (TIM) performance?

Parker Chomerics’ standard test method of characterizing TIM performance is by ASTM D5470.

What is the output of ASTM D5470 thermal conductivity test?

ASTM D5470 measures thermal impedance (resistance) of a flat disk-shaped specimen or controlled volume of a liquid TIM between two flat polished calorimeter surfaces under controlled load.

What is apparent (effective) thermal conductivity?

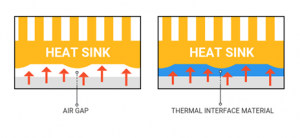

Apparent thermal conductivity is a calculated value that uses the thermal impedance (resistance) measured from ASTM D5470 and the sample thickness to calculate a thermal conductivity value. This value is influenced by how effectively the sample contacts (or “wets out”, if a dispensable) the calorimeter surfaces.

The thermal resistance at the interface between the sample and the probes is called contact resistance. Contact resistance adds to the overall thermal impedance (resistance) and may produce a lower measurement than bulk thermal conductivity.

What is bulk thermal conductivity and how is it determined?

Bulk thermal conductivity is an intrinsic property of any homogenous material. To measure bulk thermal conductivity, we must subtract the contact resistance from the individual ASTM D5470 thermal resistance measurements.

This is achieved by measuring thermal impedance (resistance) of the material at multiple thicknesses (at least three) and generating a straight-line plot. The y-intercept of that plot is the total contact resistance and the slope can be converted to bulk thermal conductivity.

Why is apparent thermal conductivity useful?

A material can have a very high intrinsic bulk thermal conductivity but be outperformed by a material of lower bulk conductivity that is softer and conformable. Measuring apparent (effective) thermal conductivity can help better identify real world performance of a thermal interface material in many cases.

Is there a correlation between apparent and bulk thermal conductivity?

Generally, there is no “go-to” correction factor or simple equation to “convert” from apparent to bulk conductivity. The contact resistance can vary widely across different thermal interface materials and there are also many other factors to consider including pressure during test, flatness and thickness uniformity of sample, contact area, etc.

Both apparent and bulk conductivity are useful values for fully understanding a thermal interface material’s performance and expected behavior in application. It is useful to consider the bulk thermal conductivity as the maximum attainable thermal transfer efficiency parameter while apparent thermal conductivity values can offer an indication of how well the material performs in real world application where contact resistance cannot be ignored.

What shoeetsuld be considered in comparing reported thermal conductivity values for materials from varying sources on supplier data sheet?

It is always difficult to compare values since it is unlikely that reported values from varying sources were generated using the same test method and parameters. There are many test instruments and methods used in the marketplace. Parker Chomerics relies on ASTM D5470 for accuracy and reliability.

The selector must be sure to consider test method used as well as any parameters used in the test that would influence outcomes (temperature, pressure, etc.). In addition, it is important to be aware of any “modified” methods reported. Without knowing the nature of the modifications, one can fall victim to overstatements of product performance.

What thermal data does Parker Chomerics report and what is the frequency that these measurements are made for Parker Chomerics products?

Parker Chomerics reports bulk thermal conductivity for most TIM products on technical data sheets. Thin bond line products (such as phase change materials and thermal greases) data sheets will show thermal impedance at fixed pressure instead of bulk thermal conductivity as this is more practical and useful to the designer.

For lot-to-lot conformance testing, Parker Chomerics measures and retains apparent thermal conductivity and thermal impedance for every manufacturing lot of product.

We hope we have answered a few important questions, but if you have any further questions or would like a sample, please do not hesitate to contact us.