Viscosity vs. Flow Rate – What is more important when measuring thermal pastes and gels?

A frequently asked question by our customers is the reason why the flow rate is given on data sheets of thermal pastes and gels instead of viscosity. And that is also a legitimate question.

Viscosity is a basic property of liquids such as heat-conducting pastes. However, measuring viscosity is more complicated than you might think.

Viscosity is a measure of the flow resistance of a liquid. Many materials are Newtonian liquids, which means that their viscosity does not change depending on the applied stress. The viscosity of Newtonian liquids can be measured quickly and easily using a rotary viscosimeter, and a single viscosity value can be specified for these test conditions. This value can be entered in simulations or used to compare products at a glance.

Parker Chomerics THERM-A-GAP Thermally conductive GEL belong to a class of liquids called “thixotropic”.

In case you do not know: Thixotropia refers to a time dependence of the flow properties in non-Newtonian fluids, in which the viscosity decreases due to persistent external influences and only returns to the initial viscosity after the stress has been completed.

This stress is caused during mixing, pumping or dismitting of the product. The extent of the decrease in viscosity depends on the duration and strength of the stirring, and the viscosity gradually recovers over time after the processing has finished. The measurement of viscosity thus leads to liquefaction of the materials. Therefore, in order to collect repeatable data, the test duration and relaxation time between tests must be carefully controlled.

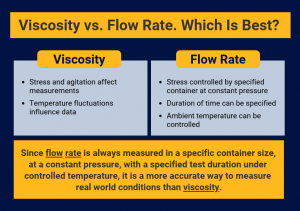

In addition, the viscosity is strongly influenced by the sample temperature. A warmer thermal paste flows faster than a heat paste at room temperature. A property that is particularly relevant for materials with thermal interfaces. A viscosity measurement is accurate only for the current time, duration and temperature. The resulting viscosity value is therefore difficult to generalize. It is therefore more appropriate to use the flow rate, as it is a measurement more representative of the actual end-use conditions.

Automated dispensing is one of the main advantages of dissipated thermal conductive pastes. Publishing flow rate data provides a framework for comparing different gels based on their delivery capability.

In addition, the measurement of the flow rate instead of the viscosity controls the critical parameters described above, such as:

- Voltages controlled by dispensing from a specific container at constant pressure

- Test duration

- Ambient temperature

The measurement of the flow rate is repeatable and more representative of the actual output situations than a viscosity value.

So the next time you read a datasheet, you’re armed with the knowledge that the flow rate is a more accurate representation of the real conditions.