What You Should Know About Electrically Conductive Elastomers

Electrically conductive elastomers are elastomeric polymers filled with metal particles. They can be grouped by filler type and elastomer type. Then within each of these classes, there are standard materials and specialty materials.

Parker Chomerics manufactures electrically conductive elastomer gaskets, also known as EMI elastomer gaskets, under the CHO-SEAL brand. We won’t get so much into gasket configurations and dimensions here, we’ll just stick to classes of materials. So what is available? Let’s find out.

Conductive elastomers are metallic particle-filled elastomeric polymers, the particles giving the shielding performance and the polymer making them “rubber.” There are many materials within this generic material type, but we’ll focus on the below.

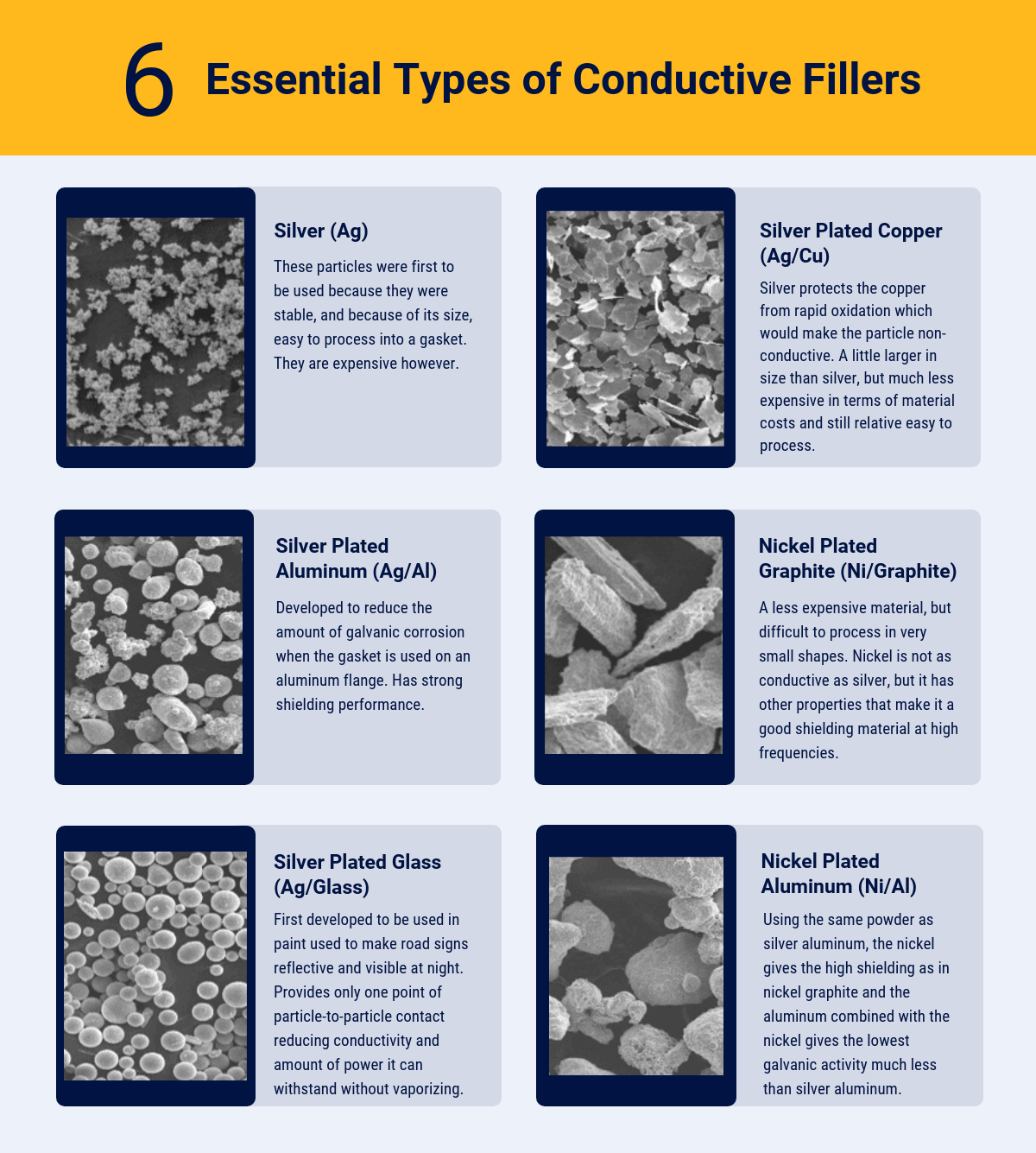

Particle fillers

Setting up the grades of conductive elastomers by filler types involves six different particles:

Three types of elastomer material

- Silicone

A polymer that has a large temperature range especially on the low end down to -55F. It is a very soft material with a low compression set. - Fluorosilicone

Close to silicone, but will not swell and degrade when exposed to solvents, fuels hydraulic fluids and other organic fluids. Although slightly harder than silicone, it is still relatively soft with low compression set properties. - Ethylene propylene diene monomer (EPDM)

Does not have the temperature range nor the softness of silicone, but is resistant to highly chlorinated solvents used for compliance with NBC decontamination and is only used for applications with those needs.

All of these materials are cured or cross-linked when the gasket is made. The cure either happens with heat or atmospheric moisture.

Three main processes used to process the material into a gasket

- Compression molding – uncured material is placed into a mold that has a cavity machined into it. The mold is closed, put into a press, then with heat and pressure the material is formed into the gasket shape mirroring the cavity and cured with heat. This process is used for sheet stock also.

- Injection molding – instead of hand loading the mold with approximately the proper amount of material, the mold is closed, then the proper amount of material is injected into the cavity. The process is much faster and because the right amount of material is injected tighter size tolerances can be obtained. Injection molding tooling is more expensive than compression molding.

- Extrusion – raw material is pushed through a die with the cross section machined into it to create extruded cord stock. Heat is applied on the die and a finished continuous gasket strip is made. These gasket can be supplied in lengths or cut to size and then corners or intersections glued or spliced together to make a ready to use gasket.

In general, for small cross sectional electrically conductive elastomer shapes, the smaller the particle the more producible the part will be. Particle fillers have little to do with mechanical properties of the gasket except that they simply increase hardness.

An overview of the different CHO-SEAL materials can be found here.

We will be happy to help you with the selection or advise you which material makes the most sense in your case. Please feel free to contact our team directly here!