Can O-rings be used in rectangular or non-circular groove patterns?

Can O-rings be used in rectangular or non-circular groove patterns?

This question comes up weekly, and the answer is a resounding “Yes!” however there are definite guidelines we want to follow.

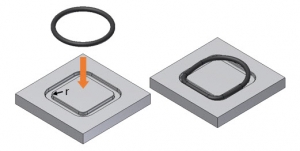

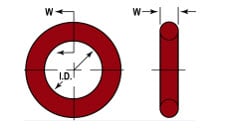

A non-circular face seal footprint might also be called a racetrack groove, a wandering groove or a custom plan view. When using an O-ring, the main design consideration is the corner or smallest radius (shown “r” in diagram). The inside radius should be at least three times the O-ring cross sectional diameter. In a perfect world, six times greater is even better. What we want to avoid is over-stressing the O-ring around the bend, or causing a corner crease which increases likelihood of corner leakage. Designing the radius at six times the cross section will minimize the bending stress, resulting in increased service life.

Ideal design: r > 6 x W diameter but no less than r > 3 x W diameter

To minimize installation difficulties arising from stretch or OD compression on the seal, the centerline perimeter of the groove should match the centerline circumference of the O-ring.

In order to produce a gasket-in-a-groove system which will not fail, the designer must consider three mechanical causes of seal failure:

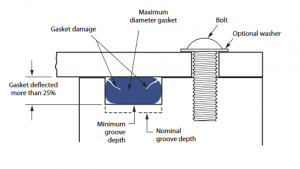

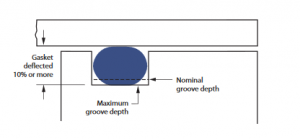

1. Gasket over-defection and associated damage

Problem: Gasket too tall for minimum groove depth (deflection beyond elastic limit). Results in gasket damage or fracture

Solution: Over-deflection avoided with smaller maximum gasket diameter and/or deeper minimum groove depth

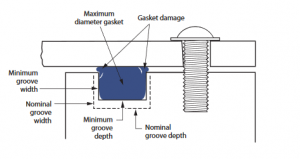

2. Groove over-fill, which can destroy the gasket

Problem: Minimum groove dimension cannot accommodate maximum gasket diameter, resulting in gasket damage

Solution: Groove over-fill avoided with smaller maximum gasket diameter and/or greater minimum groove depth and/or width

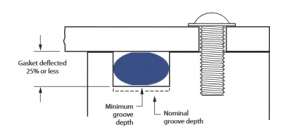

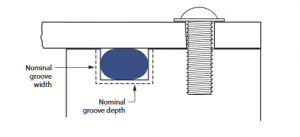

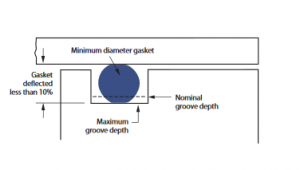

3. Gasket under-deflection as loss of seal

Problem: Gasket will not be deflected the recommended 10% minimum. Combined effects of tolerances, cover bowing, and lack of conformity can result in complete loss of cover-to-gasket contact over time, and consequent seal failure

Solution: Under-deflection avoided with larger minimum gasket diameter and/or shallower maximum groove depth

The key to success lies in the selection of the appropriate gasket size and gasket material and the careful design of the appropriate groove.

EMC gaskets are available in virtually any material and are designed in the optimum size and configuration for each unique application.

Our engineers will be happy to assist you with your groove design or a custom seal.

Contact us right here.