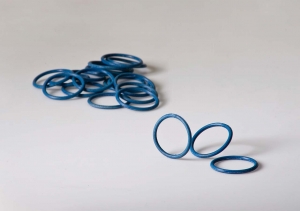

EMC shielding gaskets: Spliced gaskets according to your requirements

EMC shielding gaskets such as conductive elastomer gaskets are available in many different materials and in an almost unlimited number of shapes and sizes.

They usually consist of a base material of silicone or fluorosilicone with additional conductive fillers such as silver, silver-plated aluminium, nickel-plated graphite and others. Electrically conductive elastomers represent one of the most versatile products in the category of EMC shielding gaskets.

From the manufacturing point of view, there are two key processes: Splicing and moulding. In this article we would like to go into more detail about splicing and provide you with information about this process.

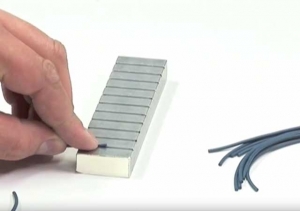

How does splicing work?

Conductive elastomer seals are often extruded in long strips, which are available in bulk or cut to specific lengths. After the extruded EMI elastomer gaskets have been cut to length, the ends are joined together with a special compound. Using a special tool, the compound is vulcanized at a pressure of 1 t and a temperature of 200 °C. The last operation is the deburring of the O-ring. A production video can be found here.

Thanks to our several splicing furnaces, we are able to produce conductive O-rings as well as more complex frame gaskets in the desired number and size according to your individual requirements quickly and reliably.

Advantages of splicing

· Hundreds of standard extrusion profiles manufactured for almost all current design requirements.

· If O-ring sizes or design requirements change, splicing can usually accommodate these changes without significant lead time or cost.

· Very few or no tools are required, which means a low upfront investment.

· Can be used with hollow section profiles, creating parts that can accommodate housings with low compressive force.

We supply conductive O-rings and seals according to YOUR requirements

We would be pleased to help you select the right material and support you in calculating the size suitable for your groove. Even small quantities are no problem and we deliver with our usual quality and short delivery time.

Do you have an inquiry? Then contact us right here.