How to Properly Choose Commercially Available O-Ring Cross Sections

There are many different cross sections for an O-ring.

Or maybe you are wondering if one O-ring thickness is better than another.

This question is posed to us several times a week and I suspect you have the same question if you have searched out this blog. This short article will walk through some of the design considerations for selecting a standard, commercially available O-ring for an application.

Design Considerations

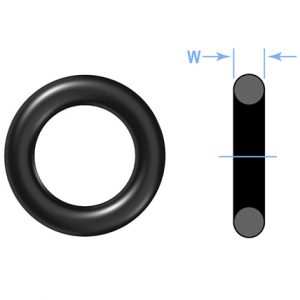

Hardware geometry and limitations are the first consideration. A traditional O-ring groove shape is rectangular and wider than deep. This allows space for the seal to be compressed, about 25% (for static sealing), and still have some excess room for the seal to expand slightly from thermal expansion or swell from the fluid. Reference Figure 1 as an example. Once the available real estate on the hardware is established, then we look at options for the O-ring inner diameter and cross-section.

Why choose one thickness seal over another?

There are several reasons to go with a thicker cross-section and a few different reasons why you might want to select a thin cross-section.

Compression Set

Tolerances

Contact Width

Dynamic Seals

Installation

If you have other questions about seal selection, please reach out to one of our Application Engineers and we will be happy to talk with you.